19 March 2009

ARID Technologies, Inc. today announced that Petro-Diamond, Inc (PDI), headquartered in Irvine, CA, has installed ARID's CRU (Carbon Retrofit Unit) Membrane System Gasoline Vapor Recovery System at its Long Beach, CA, bulk fuel terminal. Petro-Diamond joins a growing list of petroleum distributors who have chosen ARID's membrane technology as their vapor recovery solution.

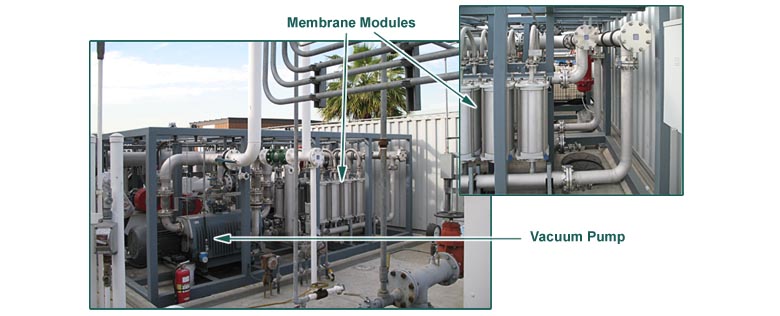

Petro-Diamond's terminal is designed and operated for the purpose of receiving, storing and delivering gasoline, oxygenates and diesel fuels via the truck rack to Petro-Diamond Incorporated's (PDI) customers. Displaced gasoline vapors (from the tanker loading operation) are collected and routed directly to the ARID CRU. The ARID unit selectively separates hydrocarbon vapors from air, and the outlet stream from the ARID unit, which has been depleted of hydrocarbons, is then routed to the inlet of a McGill dual bed carbon adsorption unit. The McGill unit consists of two carbon beds operating in tandem; the vapors pass through one bed while the other bed is being regenerated. As the vapors travel through the carbon bed, any remaining hydrocarbons in the stream are adsorped by the carbon and clean air is exhausted to the atmosphere. The beds are regenerated on a 15-minute cycle.

The growing business volume in its Southern California base identified a need for Petro-Diamond to simultaneously fill more tanker trucks while still maximizing its capture of product and meeting all environmental requirements. The existing McGill carbon bed system was unable to accommodate the increased throughput desired. After the ARID CRU membrane stage was installed upstream of the carbon bed system, Petro-Diamond was able to go from 4 loading arms to 9 loading arms operating simultaneously. South Coast Air Quality Management District's emissions standard for this terminal was set at 0.065 lbm HC (pounds of hydrocarbons) per 1,000 gallons of fuel loaded. A recent CARB emission test (California Air Resources Board) conducted on 21 January to 22 January 2009 measured an emissions level of .0011 lbm HC/1,000 gallons loaded. This emission was only about 1/60th of the allowable level.

Petro-Diamond was very pleased with the results of adopting the ARID CRU. Pat Kennedy, the Long Beach, CA Terminal Manager stated, ''With the PERMEATOR membrane unit installed, the carbon beds regenerate faster than I've ever seen. On a 15-minute cycle, we achieved a deep vacuum, which indicates a clean bed, in about 2.5 minutes.'' Petro-Diamond's Mike Dougherty (General Manager) added, ''The older carbon adsorption unit would require a large capital investment for replacement and would still struggle with processing components added to our gasoline such as Ethanol. With the Membrane Retrofit option, our carbon bed is usable as-is, and the membrane unit removes the highly polar, hard to treat components before they reach the carbon beds.'' In addition, Petro-Diamond's Eric Conard (Manager, Environmental), observed, ''Why use a flare or burner ever again; with the prevailing price of gasoline, recycle and re-use seem to make a lot more sense than combustion.''